Repair

Kumi Restoration Case

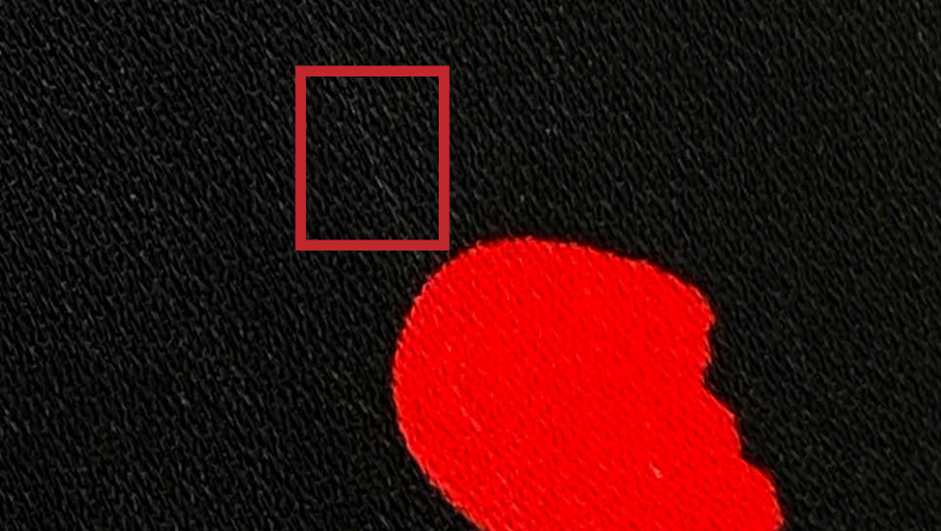

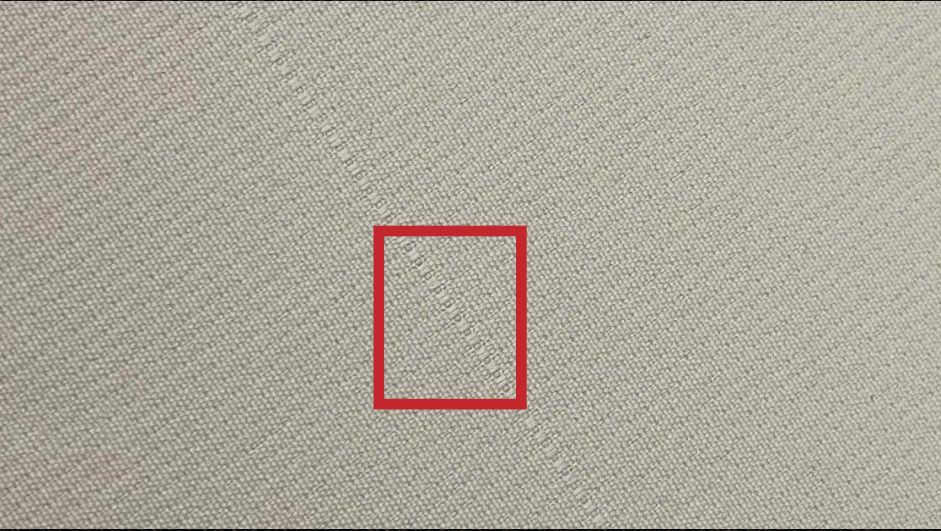

Color

When the cloth surface is dyed and printed, it is stained with other colors, which affects the appearance; if it is serious, it cannot be used, increasing the rate of changing pieces in garment factories and raising production costs.

|

| Before restoration |

|

|

After restoration

|

crossbar

The fiber type of the yarn at the transverse part is different from the fiber type of the yarn at the normal part of the fabric, and the lot number is different.

|

| Before restoration |

|

| After restoration |

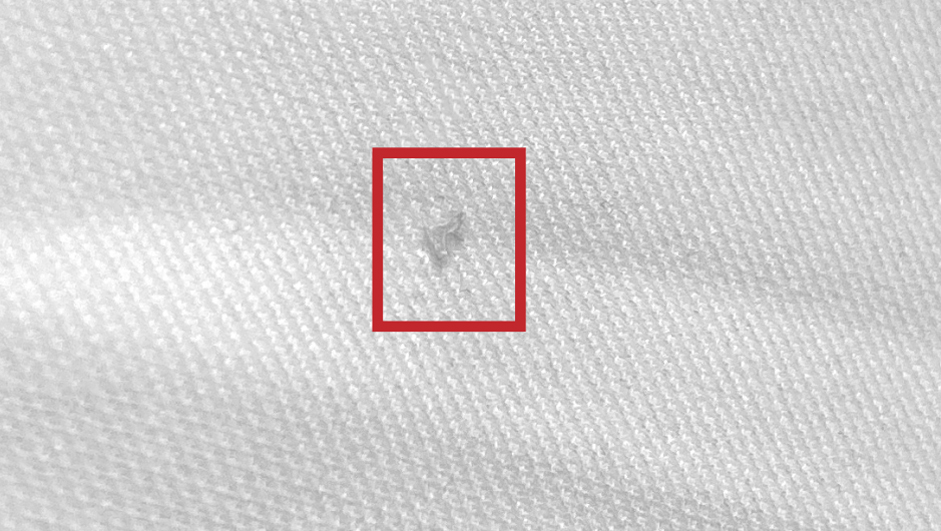

Hooks

The fabric rubs against sharp objects, causing the yarns of the tissue to be hooked out or broken, in loops or with the ends exposed on the surface of the fabric.

|

| Before restoration |

|

| After restoration |

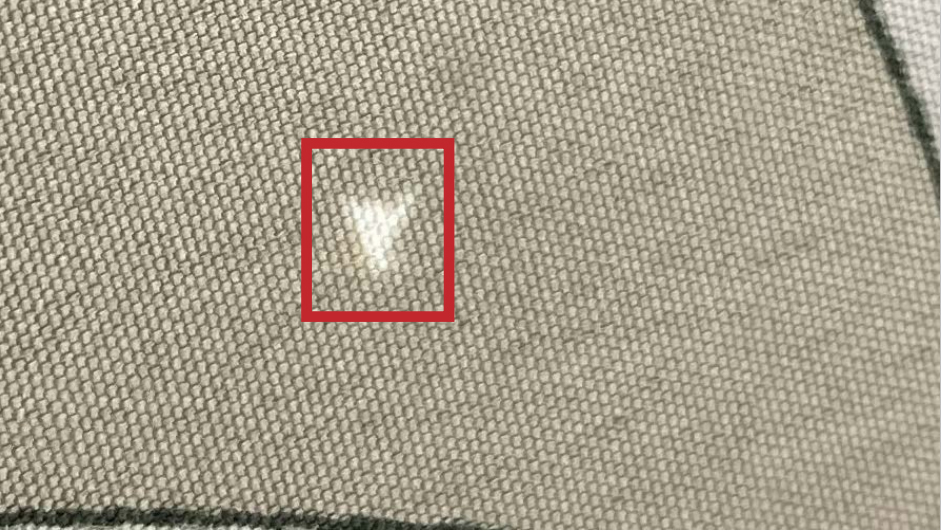

Abrasion

Abrasion of the yarn being knitted or of the finished fabric, resulting in loss of fiber orientation and distortion of the fabric's appearance.

|

| Before restoration |

|

| After restoration |

Broken Woof

Yarn tip tangle or bend type broken weft, there is a slight tangle or bend at the weft tip on the right side of the fabric, forming a short weft and producing a stop table.

|

| Before restoration |

|

| After restoration |

Yarn knot

Raised threads on the fabric surface due to yarn barging or twisting and winding.

|

| Before restoration |

|

| After restoration |

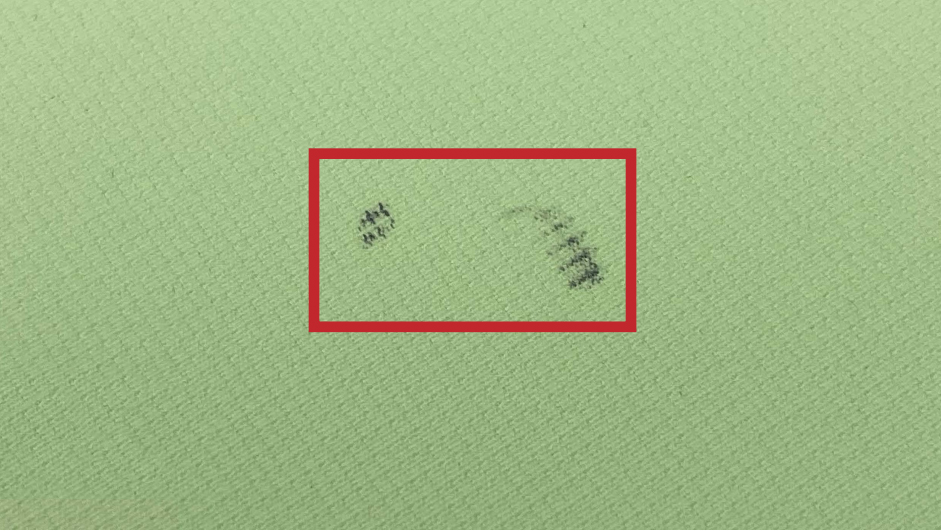

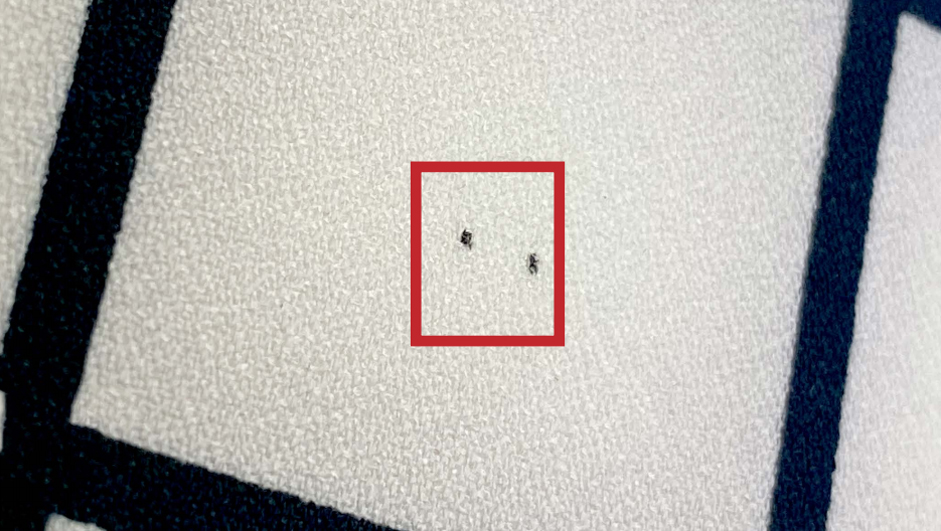

Color Point

Improper choice of dyestuff, poor dissolution, poor water quality, unclean equipment, additives and other causes of color spots.

|

| Before restoration |

|

| After restoration |

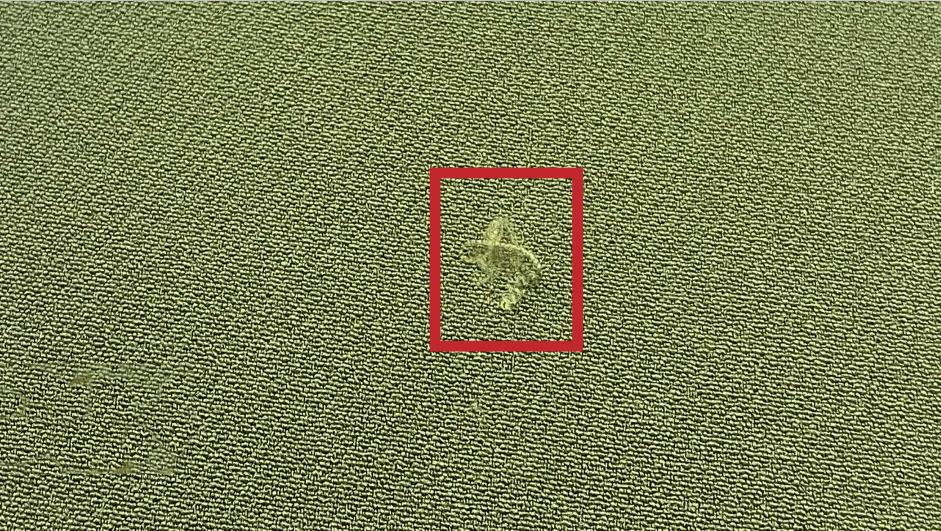

Plug Net

Fabric in the printing process appears local pattern color lightening, the whole layout pattern color degradation, pattern lack, pattern colorless.

|

| Before restoration |

|

| After restoration |

Suzhou Jiumi Textile Technology Co., Ltd.

TEL: 0086 512-63187798

E-mail: jiumijianpin@163.com

Copyright © 2021 Suzhou Jiumi Textile Technology Co., Ltd. All rights reserved. This site has IPV6 support

ICP:苏ICP备17054540号 Powered by 300.cn